Common applications for Refrion dry and adiabatic coolers are for the HVAC market.

With over 60,000 product variations, Refrion are able to provide the heat rejection needs for any application within the HVAC sector.

All units are tested at the factory to ensure high reliability is achieved on site and the highest level of quality is maintained.

Typical applications include:

- Remote cooling for water cooled chillers

- Additional free cooling for air cooled chiller applications

- Heat rejection for water cooled VRF applications

Water Cooled Chiller Applications

Dry coolers are the perfect alternative to cooling towers to provide the heat rejection requirements for water cooled chilers in applications where lower maintenance are required and a higher condensing temperature is permissible. Where the condensing temperature needs to be similar to that possible with cooling towers, Refrion’s adiabatic systems can be the perfect solution.

Since dry coolers and certain adiabatic cooler systems are not required to be notifiable to the HSE, ongoing legionella risk management is not required.

Water Cooled Chillers with Free Cooling

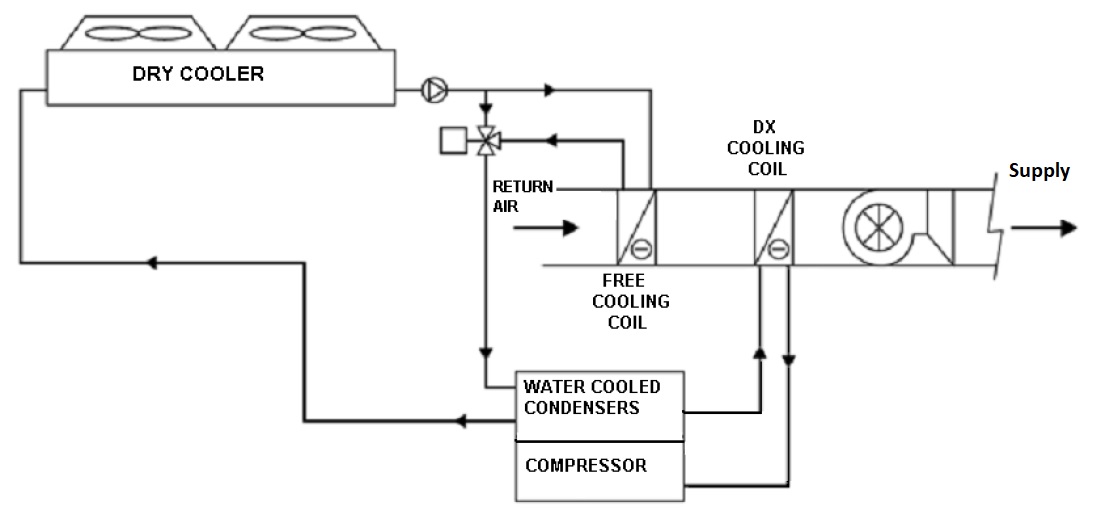

A typical application using water cooled chillers with dry coolers for heat rejection and free cooling is shown in the image below:

Air Cooled Chiller Applications

Many chiller manufacturers now offer both free cooling chillers and ‘glycol free’ free cooling chillers. There are situations, however, where the more traditional approach of incorporating a separate dry or adiabatic cooler for free cooling purposes can offer benefits, such as:

- Increased free cooling output for glycol-free applications. Firstly, most commercial ‘glycol free’ free cooling chillers incorporate a plate heat exchanger (PHE) that has an appproach or around 2-30C, i.e. the difference between the glycol temperature leaving the free cooling coil and the water leaving the PHE upstream of the chiller cooler. This can have a large impact on the free cooling capabilities for a chiller with a given footprint. By incorporating a separate dry or adiabatic cooler for free cooling purposes along with a bespoke PHE, this ‘approach’ can be reduced to as low as 10C, thereby increasing the available free cooling.

- Increased efficiency. Since air cooled chillers with integral free cooling incorporate an additional coil that sits over the condenser coil upstream, the fans most overcome this additional pressure drop. Therefore, an identical ‘mechanical cooling only’ chiller in terms of footprint and operating conditions will have a higher EER. Therefore, some applications that require air cooled chillers to meet minimum EER values may benefit by incorporating standard ‘mechaanical cooling only’ chillers with separate dry/adiabatic coolers for free cooling.

- Flexibility to meet space or sound constraints. Since a standard ‘mechanical cooling only’ chiller will generally be physically smaller than an idential free cooling chiller (in terms of capacity, efficiency and sound level) there can be applications where the smaller chiller with separate dry coolers for free cooling will suit the spacial constraints better. Likewise, for applications that require a very lower sound level from the rooftop plant, a standard ‘mechanical cooling only’ chiller will generally have a lower sound level than a free cooling chiller of identical physical size.

Water Cooled VRF Applications

With the current F-GAS regulations and rapidly rising costs of common refrigerants, water cooled VRF systems are becoming more popular as an alternative to traditional VRF systems that incorporate lengthy refrigerant pipework runs and high refrigerant quantities.

Such systems incorporate a localised water-cooled condenser that requires an external means of heat rejection. Refrion dry or adiabatic coolers are the perfect solution for these applications.