THE FIRST LABORATORY IN EUROPE SPECIALISING IN PERFORMANCE TESTING OF EVEN THE LARGEST AND MORE POWERFUL DRY COOLERS.

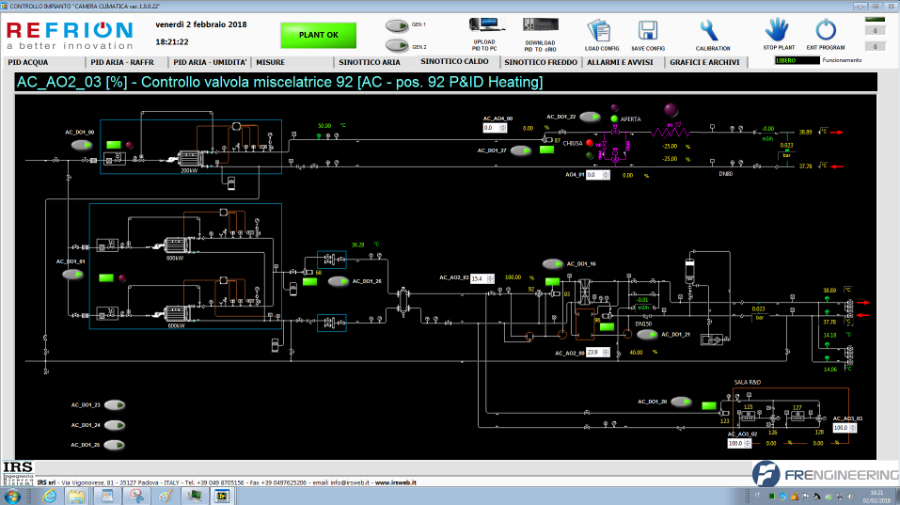

Refrion has designed and created its own climatic chamber that has few equals in Europe.

Since 2014, the performance of all the Refrion Dry Coolers and air-cooled condensers has been guaranteed through the Eurovent certification program.

Now, with the climatic chamber, Refrion can certify the units’ performance not only under standard test conditions (EN 1048), but in particular under the exact operating conditions defined by the customer.

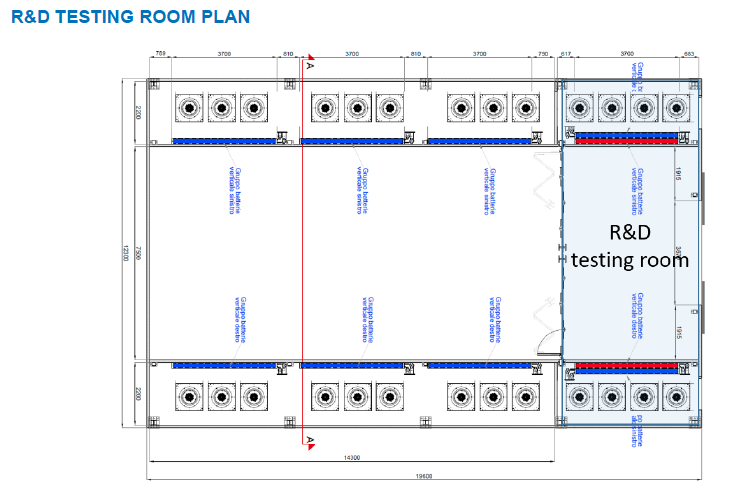

It will also be possible to test all units not covered by the certification program, such as for example units equipped with adiabatic saturation systems, centrifugal fans, or with power supply at 60 Hz frequency. The climatic chamber can be divided crosswise to adapt quickly to the size of the unit under test.

One particular area will also be dedicated to testing prototypes to speed up and validate the activity of the Refrion Research and Development Department.

Since 2014, the performance of all the Refrion Dry Coolers and air-cooled condensers has been guaranteed through the Eurovent certification program.

Now, with the climatic chamber, Refrion can certify the units’ performance not only under standard test conditions (EN 1048), but in particular under the exact operating conditions defined by the customer.

It will also be possible to test all units not covered by the certification program, such as for example units equipped with adiabatic saturation systems, centrifugal fans, or with power supply at 60 Hz frequency. The climatic chamber can be divided crosswise to adapt quickly to the size of the unit under test.

One particular area will also be dedicated to testing prototypes to speed up and validate the activity of the Refrion Research and Development Department.

The climatic chamber has been built on the site of the Talmassons (UD) headquarters and will be able to reproduce both the operating (temperatures, flow rates and pressure loss of refrigerant fluids) and the environmental conditions (temperature and relative air humidity) defined by our customers in the scale design phase of the unit.

The intake and outflow temperatures and pressures of the operating fluids and their flow rate, the temperature, relative humidity and air flow inside the chamber will be measured directly, as well as the electrical power and current consumed. It will therefore be possible to accurately calculate the thermal exchange capacity and the energy efficiency coefficient. It will also be possible to perform measurements of the noise level of the units through a sound intensity sensor (ISO 9614-1).

The intake and outflow temperatures and pressures of the operating fluids and their flow rate, the temperature, relative humidity and air flow inside the chamber will be measured directly, as well as the electrical power and current consumed. It will therefore be possible to accurately calculate the thermal exchange capacity and the energy efficiency coefficient. It will also be possible to perform measurements of the noise level of the units through a sound intensity sensor (ISO 9614-1).

CHAMBER DIMENSIONS:

OVERALL

LENGTH: 19,6 m

WIDTH: 12,3 m

HEIGHT: 8,5 m

R&D TESTING ROOM

LENGTH: 4,7 m

WIDTH: 7,5 m

WIDTH: 7,5 m

HEIGHT: 6 m

ACCEPTANCE TESTS ROOM

LENGTH: 19,2 m

WIDTH: 7,5 m

HEIGHT: 6 m

LENGTH: 19,2 m

WIDTH: 7,5 m

HEIGHT: 6 m

MAX SIZE OF TESTABLE UNITS:

LENGTH: 14 m

WIDTH: 3 m

WIDTH: 3 m

HEIGHT: 3,5 m

PERFORMANCE TESTING AND ASSESSMENT:

- Thermal exchange capacity according to Eurovent standards (EN 1048)

- Thermal exchange capacity under customer-defined conditions

- Thermal exchange capacity under free cooling conditions

- Thermal exchange capacity under high-temperature conditions

- Electrical power / current consumed

- Liquid side pressure drops

- Sound level (ISO 9614-1)

OPERATING RANGE (*):

- Air temperature: 0°C to +45°C (**)

- Relative air humidity: 40% to 70%

- Max intake liquid temperature:

- 50°C (with capacity up to 400 m3/hr),

- 100°C (with capacity up to 30 m3/hr)

- Maximum measurable exchange capacity: 2.2 MW

- Maximum air flow processed: 700,000 m3/hr

(*) The test conditions must be validated by the Refrion technical office.

(**) A maximum variation in temperature of 25K on the same test day is tolerated.