Units designed to meet the increasing demand for free-cooling applications, they optimise the benefits coming from the adiabatic saturation of the air adopting a water recirculation system and electronically commutated large-diameter fans.

The water and power consumption are thus minimised, resulting in C.O.P. maximisation and the possibility to use “free-cooling” applications throughout all the year.

The water and power consumption are thus minimised, resulting in C.O.P. maximisation and the possibility to use “free-cooling” applications throughout all the year.

Features:

- Self-draining system: no risk of water stagnation. All the water is automatically drained every 24 hours

- The system prevents the proliferation of legionella by avoiding droplets in the airflow.

- Ease of maintenance thanks to the full access to the inside of the unit; all the components of the hydraulic system are inspectable

Devices

1. EC fans Ø 1250mm

2. Main electrical panel

3. Humidity and temperature transducer

4. Feed actuated valve

5. Discharge actuated valve

2. Main electrical panel

3. Humidity and temperature transducer

4. Feed actuated valve

5. Discharge actuated valve

Recirculation system

6. Water distribution pipes

7. Recirculation pump

8. Overflow

9. Drain

10. Make-up water

11. Self-draining drip

12. Water basin

13. Heat exchanger

14. Protection grids

15. Droplet separator

16. Evaporative cooling pad

17. Inspectionable water distributor

7. Recirculation pump

8. Overflow

9. Drain

10. Make-up water

11. Self-draining drip

12. Water basin

13. Heat exchanger

14. Protection grids

15. Droplet separator

16. Evaporative cooling pad

17. Inspectionable water distributor

Adiabatic Saturation Theory

- Adiabatic saturation temperature is a thermodynamic property of humid air. It represents the temperature that can be achieved by air when it reaches saturation condition through an adiabatic transformation.

- The adiabatic saturation temperature falls – since evaporating water removes heat – though it is still higher than the dew temperature, as evaporation itself raises the partial pressure of water vapour.

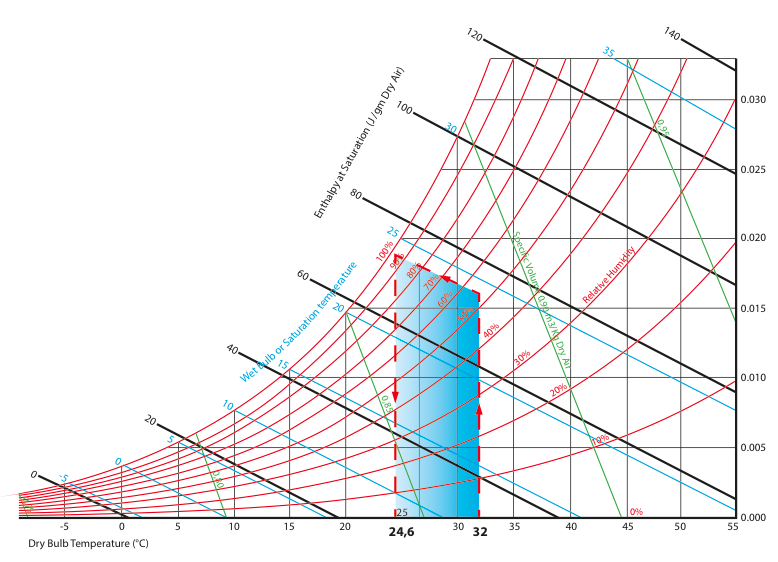

Carrier psychrometric chart at p=1,013bar:

EXAMPLE

Ambient Air Condition TAMB: 32°C Relative Humidity R.H.:50 %

Air Condition Calculation TCALC: 24.2°C Relative Humidity R.H.:92 %Due to the adiabatic saturation made possible by the Industrial Adiabatic System, the Refrion design model provides an increase in relative humidity of ∆R.H. = 42% up to a maximum R.H. = 92%.

Air Condition Calculation TCALC: 24.2°C Relative Humidity R.H.:92 %Due to the adiabatic saturation made possible by the Industrial Adiabatic System, the Refrion design model provides an increase in relative humidity of ∆R.H. = 42% up to a maximum R.H. = 92%.