Refrion offer different adiabatic cooling solutions to suit different application requirements.

Adiabatic Spray System

Spray water is pressurized and supplied through an array of nozzels into the incoming air supply, adiabatically cooling the airstream towards saturation.

Industrial Adiabatic Pad System (Open or Closed)

High efficiency adiabatic pads are installed on the inlet side of the coils and water is supplied through a supply pipe at the top of the pads, cascading down the pads into a drain tray below.

With this system, a high level of adiabatic cooling of the supply air is achieved without any risk of the adiabatic water reaching the coils.

Two systems are available, open of closed:

- Open: Water cascades down without any recirculation.

- Closed: Water is collected at the bottom of the pads for recirculation.

Hybrid System

Spray water is pressurized and delivered through an array of nozzels directly onto the coils, providing both high efficiency adiabatic cooling of the incoming air and direct heat-exchange cooling to the surface of the coils.

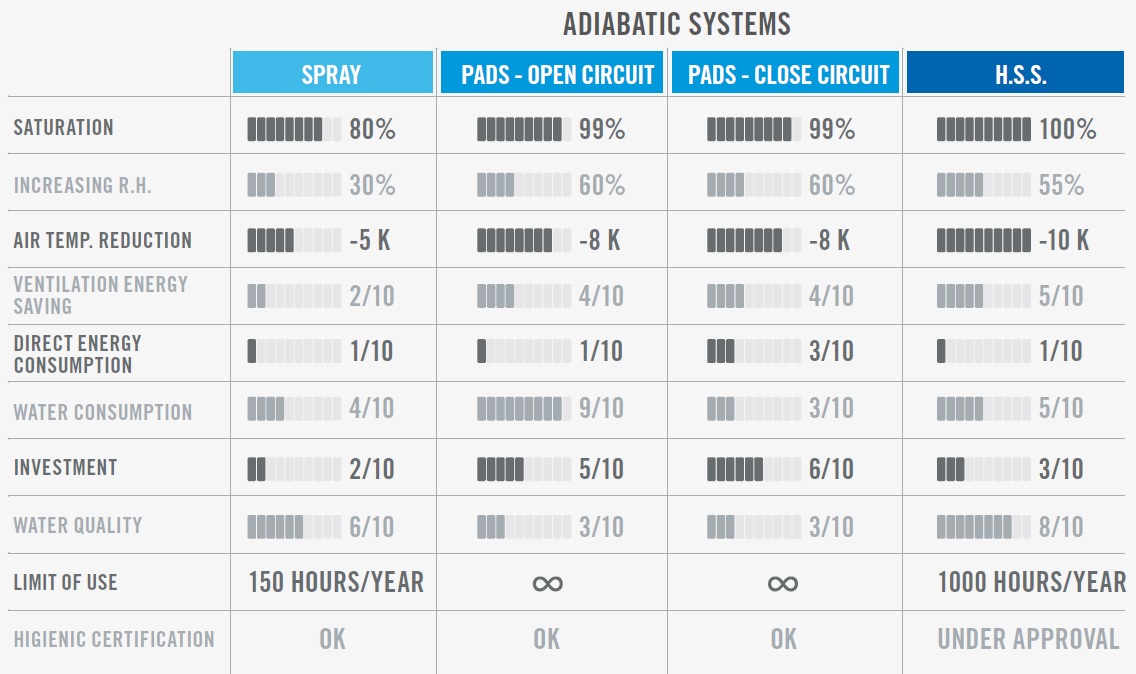

Comparison

Hygeine

All Refrion adiabatic systems are compliant with VDI 2047 Part 2, with the exception of the Hybrid system which is currently under approval.

All systems are provided with the following to ensure Legionella cannot present an issue:

- UV filtration directly before the water supply outlet

- Integral controls to ensure water is not allowed to stand within the adiabatic system or collection tank (where applicable) when the adiabatic system is not in use.

- Auto flush/cleaning cycle built into the control strategy.

- Stainless steel collection tank (where applicable) and either stainless steel or plastic pipework and fittings for the supply system.